After entering into an agreement 12 years ago, Como residents and a local manufacturing facility are still weighing how to eliminate toxic chemical emissions in the neighborhood.

A 2020 Minnesota Pollution Control Agency report, which came out last month, found the site of Greatbatch-Globe Tool, Inc. in the Como neighborhood emitting trichloroethylene (TCE) above the state-recommended levels. Community members said the neighborhood has been working with the company for years, but the chemical, widely used in manufacturing as a degreaser, continues to pose a concern in the area.

“I’m really concerned to hear about more TCE up there,” said Ward 2 City Council member Cam Gordon, who represents the neighborhood. “This actually has been an ongoing problem, I would say, for decades up there.”

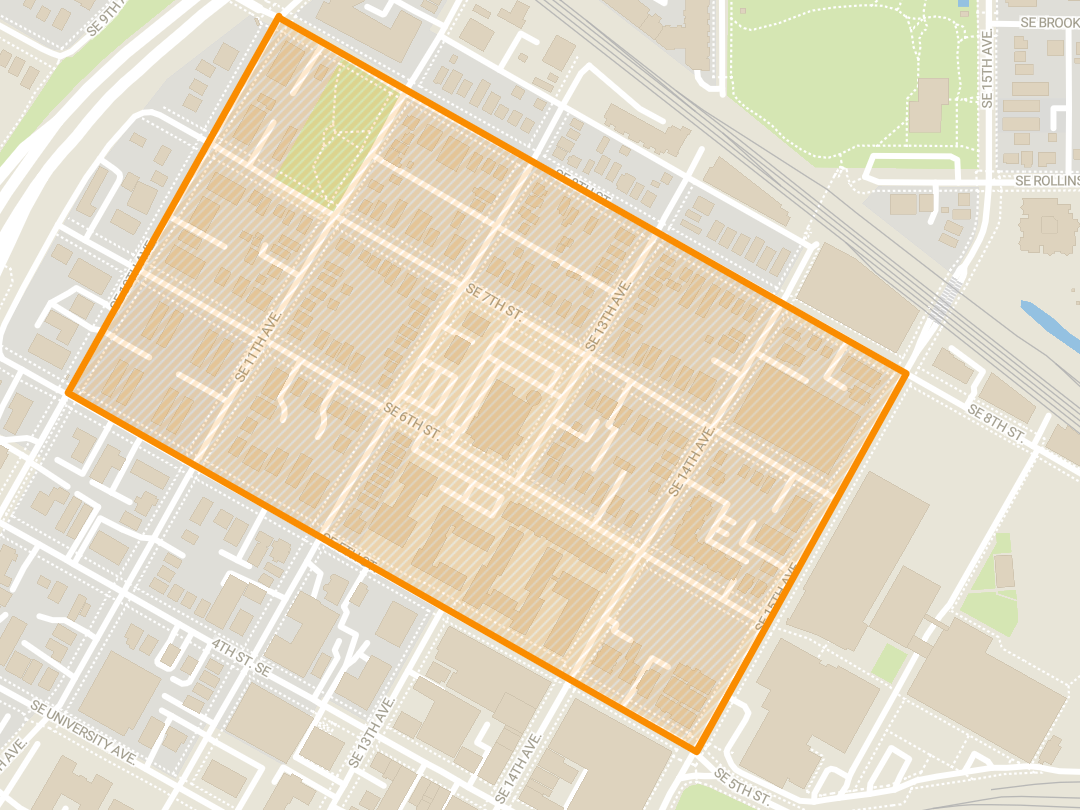

Greatbatch-Globe Tool, Inc., a subsidiary of Integer Holdings Corporation, manufactures parts used in medical implantable devices such as stents and catheters. The affected site is located in the industrial area at 730 24th Ave, just south of Elm street.

The company has said it plans to eliminate the use of TCE by December 2021 and has already made investments to make the change.

Discussions with the neighborhood

The Southeast Como Improvement Association entered into a non-binding “Good Neighbor Agreement” with Greatbatch-Globe Tool Inc. 12 years ago, pledging to reduce TCE emissions.

But after the recent report, SECIA members said the neighborhood needs to revisit the topic to find new solutions.

“We still are honoring or believing that they should be honoring our Good Neighbor Agreement,” said SECIA board member Wendy Menken, who was on the board when the original agreement was signed. “But with this air quality issue we do need to reconnect and set up a time with them when we can explore what’s going on and find out more information.”

TCE, which cleans oils off of metals, is harmless in low amounts, but sustained levels above two micrograms per cubic meters of air can affect the immune system and lead to cancer, according to the Minnesota Department of Health.

“So they set a level in which if the quality is below that [TCE] level, generally there wouldn’t be concern about that,” said Todd Biewen, who heads the MPCA’s environmental analysis and outcomes division.

Moving away from TCE in manufacturing

Greatbatch-Globe Tool Inc. has taken some steps to bring TCE an acceptable level since MPCA first alerted the facility of its finding last May, said Kelsey Suddard of MPCA’s air-permitting unit, who has monitored the facility. An air permit issued by MPCA has already laid out guidelines for the facility to reduce TCE, Suddard said.

Greatbatch-Globe Tool, Inc. has installed pollution control equipment to further reduce TCE emissions, Suddard said. While the facility has also swapped to alternative degreasing methods, TCE is still used in the manufacturing process.

“Integer continues to operate within compliance of our MPCA-issued air permit, and we have voluntarily made a $3.5 million investment in new equipment at our Minneapolis facility to meet the new emission guidelines. We are committed to completely eliminating the use of TCE by December 2021,” according to a statement from Interger.

Gordon said he would support the facility ceasing operation until TCE is fully eliminated, although that may not be viable from a business standpoint.

“I suspect they don’t want to just stop their work,” Gordon said. “[But] if MPCA wants them to just stop using it altogether, to stop their business for a while, so they get these approval from the feds, I would be supportive of that.”

Strict federal regulations for manufacturing solvents can make the process of transitioning away from TCE a lengthy one, said Laura Babcock, director of the Minnesota Technical Assistance Program at the University of Minnesota, which aims to assist local businesses in improving efficiency and reducing pollution.

Addressing the larger issue

The MPCA report was in response to pressure from the Minnesota Legislature last spring to investigate TCE more broadly. An investigation last winter found a White Bear Lake facility reported inaccurate TCE emissions data for more than a decade and exposed the surrounding community to dangerous levels of the chemical.

“It became an issue at the Legislature, and they actually gave us money … to spend time working and finding TCE and trying to reduce it at other facilities,” said Biewen from the MPCA. “And we actually did some monitoring around some of these facilities to see if we were detecting TCE in the air.”

Eighty-six facilities have been accessed by the MPCA for the chemical, according to the report. Of them, 26 were found to use the chemical in industrial processes.

Going forward, MPCA will continue to closely monitor the TCE situation at Greatbatch-Globe Tool, Inc., with plans to create more transparency for the public about emissions, Biewen said.

“We also want to get more of an online [dashboard] on these facilities,” Biewen said. “And as we continue to work with them, we can update that information, not only for the Legislature but for the public.”