A University of Minnesota outreach program is working to eliminate the use of a hazardous chemical in dry cleaners in Minneapolis and throughout Minnesota.

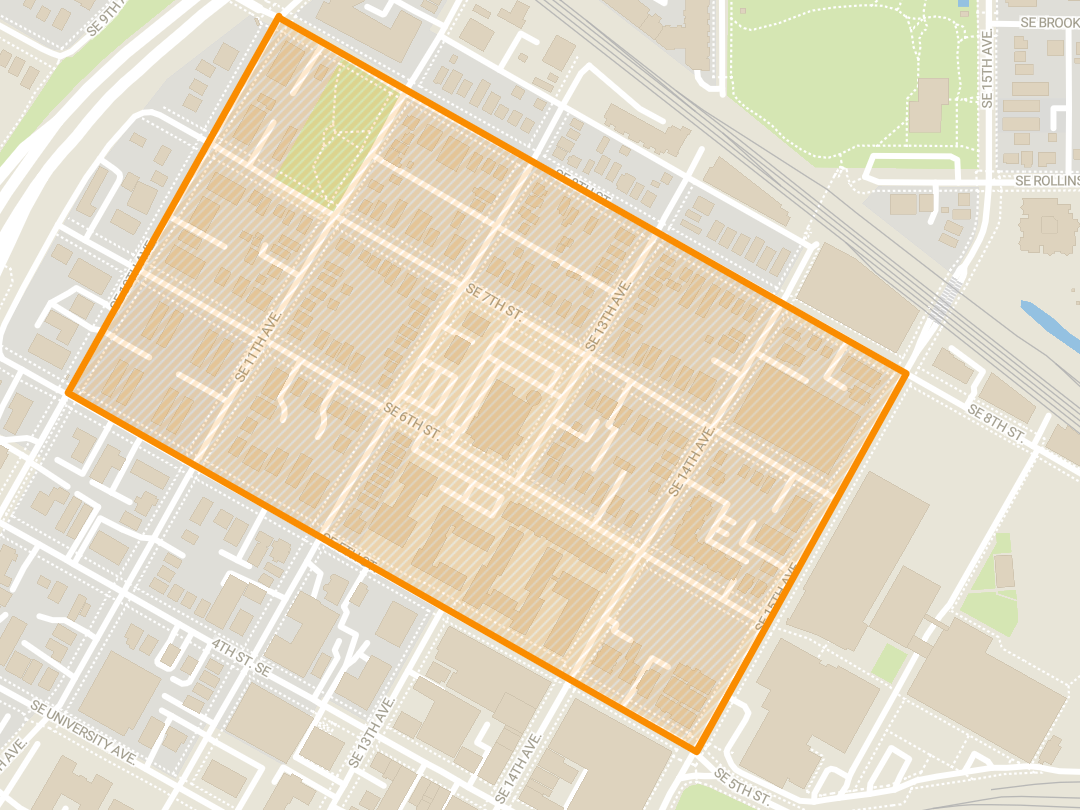

The Minneapolis City Council approved an updated ban on tetrachloroethylene, or perc, in August. The ban is the culmination of more than five years of work with dry cleaners across the city. The Minnesota Technical Assistance Program, an outreach program at the University, worked with local dry cleaners to evaluate their processes, understand the environmental impact of perc and adopt alternative solvents.

Perc is a dry cleaning solvent that effectively cleans hard-to-remove stains, making it a historically popular solution. The chemical, however, pollutes air inside and outside of dry cleaners and has been linked to nervous system and kidney damage and some cancers.

“I mean, quite frankly, it is a very good dry cleaning material. It does the work,” said MnTAP Director Laura Babcock. “It just also happens to be very toxic.”

The most recent measure closed loopholes in a previous ordinance that allowed perc in some dry cleaning uses.

After helping dry cleaners understand the negative impacts of perc, MnTAP helped inform owners about more environmentally sustainable alternatives, Babcock said.

“In our business of technical assistance, it doesn’t pay to tell people what to do. You have to kind of encourage them to change behaviors,” she said.

Educating dry cleaners about alternatives before enacting the ban helped ease the transition, said Patrick Hanlon, the city’s director of environmental programs.

“The real victory here isn’t necessarily the ban, but it’s the work that went into making this not a controversial issue,” Hanlon said.

Cost is one barrier to making the switch. To use an alternative solvent, dry cleaners have to purchase new machines that can cost more than $30,000 each.

“It’s a lot of money for a small business in what can be seen as a struggling industry, so that kind of support angle is really the most important,” said Nathan Landwehr, a waste reduction specialist at MnTAP who worked directly with dry cleaners.

To help cover these costs, some dry cleaners took advantage of the city’s Green Cost Share program, which helps businesses adopt more sustainable processes.

MnTAP now hopes to apply the model established in Minneapolis to dry cleaners across Minnesota.

“[We want to be] available as a resource for dry cleaners in the entire state of Minnesota so they don’t have to figure things out on their own,” Babcock said.

Hanlon said he hopes the continued outreach could lead to a statewide perc ban.

Today, about 100 dry cleaners operate in Minnesota. This number is down from a peak of about 350 dry cleaners in the state during the 1970s and ’80s, said Keith Aune, president of the Minnesota Dry Cleaners Association and owner of Clean’n’Press, a dry cleaner based in West St. Paul.

The decline in dry cleaners stems from changing clothing styles and more casual work settings, among other factors.

Aune said he believes a shift in the industry is coming as perc machines age and the environmental and financial costs of the solvent are recognized.

“I do think that sooner or later there’s a good chance that [perc] is out of the industry completely,” he said. “It’s just a matter of time.”

_RGB_h-01.jpg)