The witches in “Macbeth” would have had a ball with a cauldron like this.

With the concentration of a brain surgeon and the dexterity of a circus juggler, the participants in Pour Bastards: The 36th Annual Minnesota Iron Pour handled molten iron – that ranged from 2,500 degrees to 3,000 degrees – as easily as one would handle a lighter.

The approximately 40 participants hailed from Augsburg College, the College of St. Catherine, Southwest Minnesota State University and the

University of Minnesota. Students, professors and visiting artists met in the foundry of the Regis Center for Art for the sole purpose of melting down scrap radiators to cast iron sculptures.

The melting iron smelled like a charcoal barbeque without the hamburgers. The mechanisms inside the foundry looked like a cross between a Rube Goldberg machine and Willy Wonka’s factory. A 3-ton beam traveled back and forth across the ceiling as pourers maneuvered a large ladle that emptied iron into the molds.

Billed as “an aesthetic, athletic, pyrotechnic performance,” the iron pour more than lived up to expectations. The smells, the flames, the noise and the occasional spill set the stage for some impressive performances. Fourth-graders from Homecroft Elementary were the most vocal audience members.

“Mira! Mira!” – “Look! Look!” in Spanish – cried three little girls when some of the iron ran out of a mold and onto the floor.

For experienced participants like Melanie Van Houten, a little spill was no big deal. Van Houten, a University alumna, brought some of her students from the College of St. Catherine. It’s her 10th iron pour here, and she said she enjoyed this one because of the recently upgraded facilities.

“A lot of places don’t have the means for a pour like this,” she said, “and Wayne (Potratz) is well-known in the iron world, so it’s great to work with him.”

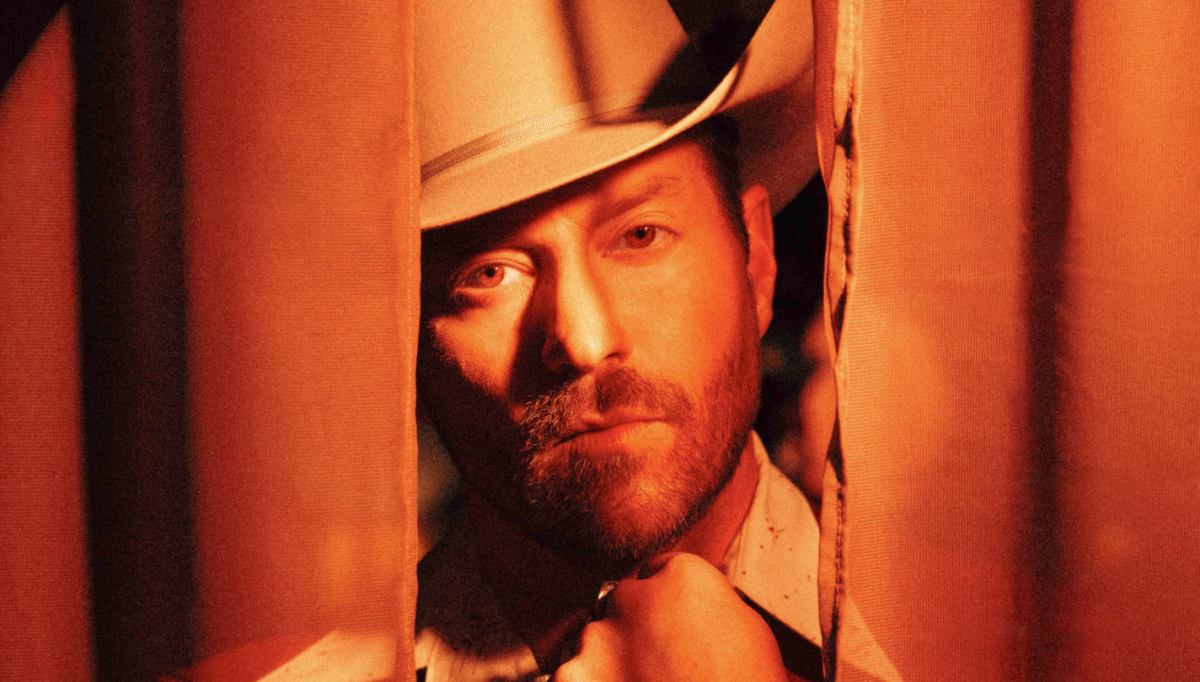

Potratz, a University of Minnesota professor, wore a green shirt with a sheriff’s badge pinned on it and was in the center of the action. He organized his crew of workers with the precision of an army general, yelling orders and directions over the roar of the furnace.

“An event of this caliber takes a lot of preparation,” Potratz said. “The fire was lit early in the morning so it would be hot enough to add the iron around 11:30.” Half an hour was allotted to melt the scrap iron, and then, the real fun began.

Participants were required to wear leather boots, gloves, aprons, coats and spats to avoid contact with the materials, along with a helmet and a wire-mesh face shield.

There was a strong sense of community among the participants, whether it was a pourer’s first or 10th iron pour. Former students brought their current students to the event, and professors and students worked side by side to make one person’s scrap metal into another person’s art.