When many people walk into the meat aisle at the grocery store, they often do not think about what goes into getting their steak or chicken on the shelf — and especially not how much water goes into its production.

In a study published earlier this month, University of Minnesota researchers make those connections about where commercialized meat comes from and how much water it takes to bring them from farm to table.

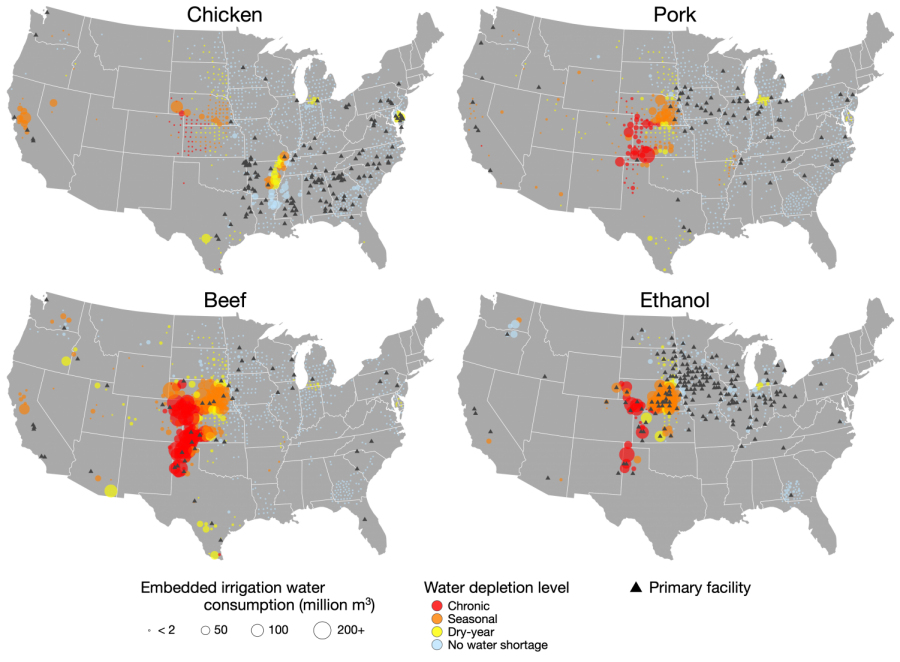

Using 2012 data, the study tracks the supply chains of some of the biggest commercial producers of beef, chicken, pork and ethanol, products that consume nearly half of the global crop production as feed and feedstocks.

This is the first time on a national scale researchers have looked at this supply chain up close, said Kate Brauman, study co-author and lead scientist for the Global Water Initiative at the University’s Institute on the Environment (IonE).

One of their most notable findings is the discovery that it is not necessarily the type of meat that has the largest environmental footprint but where the meat is sourced and how scarce water is in that region, Brauman said.

Although beef production on average is the most water-intensive meat to produce, the water needed to support chickens, pigs and other animals varies, according to the study. In areas where there is more rain, for instance, farmers require less groundwater to grow the crops that will eventually be turned into animal feed. But in areas that experience drought or have less water available, agricultural and livestock production will put a strain on the water available nearby.

“This generalized assessment for a consumer of, like, ‘Don’t eat beef because of water’ actually doesn’t hold true, and [the study] brings nuance to that,” said co-author Jennifer Schmitt, the program director and lead scientist at the NorthStar Initiative for Sustainable Enterprise at the IonE. “You should think more about where the food is coming from and what they’re doing in their supply chain to combat issues of water scarcity than just making blanket decisions.”

Water scarcity not only has negative impacts on the environment but also on residents who live in these areas and companies who have invested in these supply chains.

Farmers who do not have enough water to plant may need to delay their growing season or grow a smaller yield. Overusing aquifers can also cause the ground to sink, and, if a city does not have enough water, they may need to import water from another place, which is extremely expensive, Brauman said.

With commodity crops like corn and soy, which are normally grown in a high volume, it is harder to track where these products came from and which facility they were sold to, she said. This makes it hard to quantify the environmental impacts because, depending on where the commodity crop came from, the amount of water it used varies. Other analysis has been dependent on broad regionalized or county data, which does not give an accurate picture of where water scarcity varies area by area.

“This is a big challenge for environmental work in general. [Because] we can see all this variation, we can quantify it, but we still have a really hard time connecting that through supply chains to

businesses and to consumer products,” Brauman said.

In a collaboration with FoodS³, a food systems supply tool powered by the NorthStar Initiative for Sustainable Enterprise, researchers developed a spatial optimization model using 2012 data from industry reports, the U.S. Department of Agriculture, the U.S. Census of Agriculture and company websites. Researchers tracked how much corn and soy was produced and purchased by county and compared it with which areas have water scarcity in the U.S.

“By keeping track of that movement, we’re actually able to trace where water impacts went,” Brauman said. “And it’s really important to do this for soy and corn, for ethanol and for meat because that’s where the vast, vast majority of the corn and soy that we grow in the U.S. actually goes.”

One of their biggest audiences with this research is larger companies involved in these supply chains, she said. Their work not only highlights sustainable practices they can take but can also help them save money in the future by mitigating the risk of supply chain disruptions due to water scarcity. Schmitt said they also want to include more stakeholders in the process, including policy makers and private companies.

“I think it’s fair to say that we all want clean water, clean air and to recognize the need to slow global warming because of the effects that it’s going to have in the next couple of decades but [also] the effects it’s already having on communities across the world,” said Jacob London, a manager of investor engagement for Ceres, a nonprofit that works with companies in the food industry to improve their agricultural and water sourcing issues and set sustainability goals.

London said this study gives companies the data needed to predict and assess future risks to their supply chains. Depleted water can increase commodity prices and transportation costs and make it more difficult to rely on contracted farmers. In highlighting areas of water scarcity and directly linking feed production to specific companies, it is easier for meat companies to understand where their products are coming from and what steps they can take to become more sustainable.

“Companies in the industry oftentimes use the excuse that because it’s such a complex supply chain, it’s very difficult to get insights into how their beef or pork or chicken is getting to the restaurant … and sort of implying that it’s the suppliers responsibility to account for the sustainability effects,” he said. “And I think this study kind of puts a dent in that excuse.”