The work of University of Minnesota alumnus Dr. Aminul Mehedi in the material science field is motivated by one simple goal: mitigating climate change.

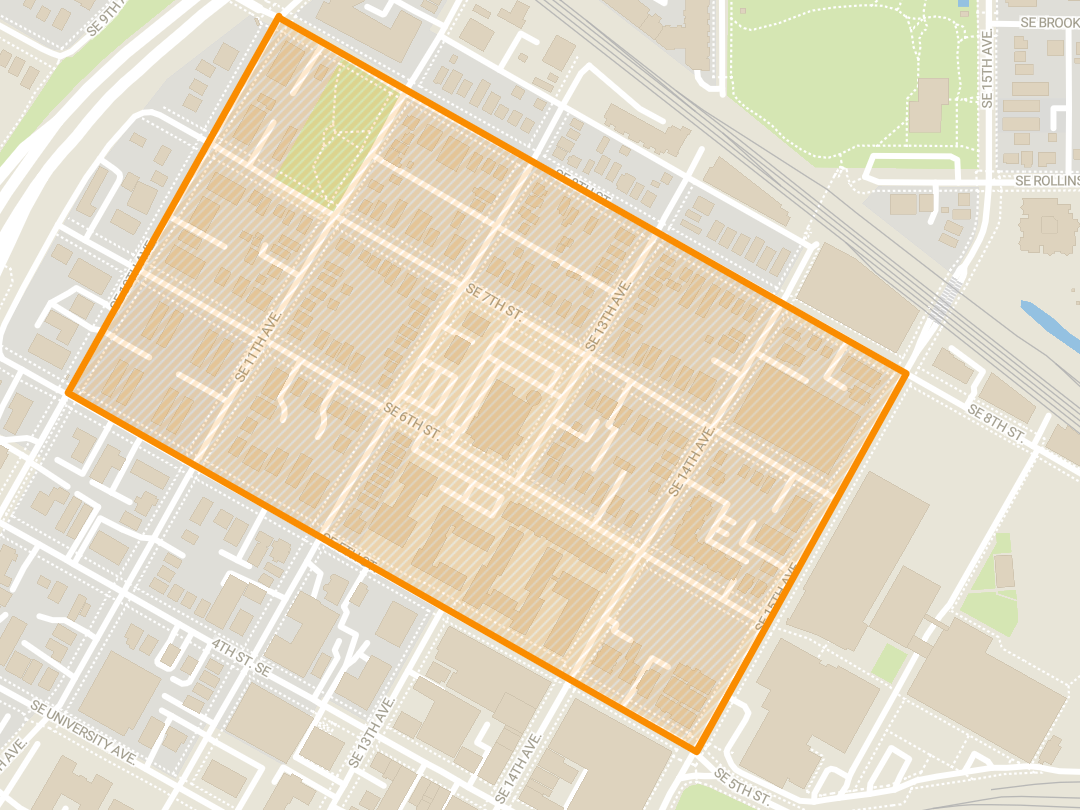

In order to achieve this goal, Mehedi has researched and developed new soft magnetic material that is capable of charging electric vehicles and other products. Mehedi’s business startup, CM Materials, received a $100,000 Encouraging Development, Growth and Expansion (EDGE) grant on Dec. 16 to continue this research and product development.

The grant will allow the startup to demonstrate how magnetic cores and powder can charge electric vehicles and be put to use in other devices.

“The EDGE Grant program is incredibly competitive,” said Jordan Schulties, division director of the Delaware Division of Small Business, the organization that awarded the grant. “Dr. Mehedi and his team successfully demonstrated that the work CM Materials is doing to help power devices in a more efficient and sustainable way will allow the company to stand out from its competitors as it takes its product to market.”

After coming to the University in 2012 from Bangladesh seeking a master’s and doctorate degree in material science and engineering, Mehedi worked alongside his advisor, electrical and computer engineering professor Jian-Ping Wang, as a researcher in his lab for six years.

Mehedi worked with soft magnetic material during his graduate program at the University, and eventually went on to win the Minnesota Cup Student Division in 2016, a large business startup competition for a new soft magnetic material called “Minnealloy.” This technology was eventually licensed to Seagate.

Mehedi also worked for the electric vehicle company Tesla and Carpenter Technology, a material manufacturing company.

Now, Mehedi’s Delaware-based company is looking to put new technology, called CleanMag, on the market for other investors, Mehedi said.

“If you need to generate, distribute or convert power, you use motors, inverters or transformers, which our electromagnetic material goes into,” Mehedi said.

The charging systems in electric vehicles rely on electromagnetic components to operate. The technology developed by Mehedi is 50% smaller and approximately 25% more efficient than competing technologies.

“I saw a gap in the market and wanted to solve it, after experiencing the customer [demand] side as well as the challenges of creating materials to provide,” Mehedi said.

By using sustainable materials and making devices smaller, there is less electric current operating in the car, which ultimately reduces energy consumption.

With its magnetic efficiency, this green technology has the ability to reduce Co2 emissions by 2.6 billion tonnes by 2050, according to Mehedi.

“I understand I am only one person and there is only so much that I can do in helping the climate crisis, but you can start small,” Mehedi said.

The United States is not considered an industry leader in this technology, as most of the soft magnetic materials in the world are controlled by China, Japan and Germany, Mehedi said. As electric cars and products become more prominent, it will be critical for the United States to have access to technology like that developed by Mehedi.

“He is a very unique student, in the way that he has a strong passion for research and learns quickly,” Wang said of his interactions with Mehedi. “I observed that he always wants to help the people as if the research can go one more step so that it can be used further on and then see what it can become.”

During his time as a University student, Mehedi was not only invested in developing new research, but also had kind interactions with those around him, Wang said.

“He represents a strong mannered program for magnetic material research,” Wang said. “He carried these forward towards application. As a professor, we want to see that.”